Description

Liquid Glucose is one of the popular food additives and ingredients in most countries. Corn Syrup or liquid glucose is made from high-quality corn starch by subjecting starch to high temperature in the presence of acids under strict quality control. A series of two enzymatic reactions are used to convert the cornstarch to corn syrup. Its major uses in commercially-prepared foods are as a thickener and sweetener. It has moisture-retaining (humectant) properties, which keep foods moist and help to maintain freshness.

As a leading manufacturer & supplier of liquid glucose, the food additive needs of the baking & confectionery industries on a global scale. Technically, glucose syrup is any liquid starch hydrolysate of mono, di, and higher saccharide, and can be made from any sources of starch; maize, wheat, rice and potatoes are the most common sources. The viscosity and sweetness of the syrup depends on the extent to which the hydrolysis reaction has been carried out. To distinguish different grades of syrup, they are rated according to their “dextrose equivalent” (DE).

Trusted Manufacturer & Exporters of Liquid Glucose Syrups

As a noted manufacturer & exporter of corn products,impresses the global markets by consistently delivering the high-quality liquid glucose syrups for use in different industries. The manufacturing process employs state-of- the-art acidic hydrolysis which ensures superior product quality, tailored to meet the end user requirements. Our liquid glucose syrup can be used along with a variety of dry solid substances; without, in any way, affecting other parameters like sweetness, ash content, acidity, etc. Important functional properties of liquid glucose syrup include high fermentability, viscosity, hygroscopic, sweetness, colligative properties and facilitates browning reaction; it adds body and mouthfeel in the preparation of various products.

Quality is at no cost compromised and is socially responsible to maintain high standards and practice above the professed standards for quality management. As the Company ventures into an export oriented manufacturing unit for Starch & Derivatives, TQM (Total Quality Management) is structured as a whole new way for success.

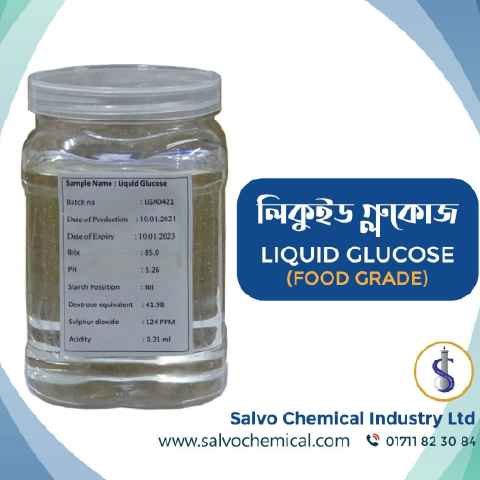

Through a highly automated and controlled process it is made sure that every stage starting from procurement of raw material to the stage of finished goods, the standards are enforced and maintained. The in-process quality control is attained through the instrumentation, which control temperature, pressure, density, flow and pH automatically. Salvo Chemical maintains a colossal in-house laboratory fully equipped with latest equipments to check the product specification. Utmost care is taken of purity, hygiene and nutrition so that the yield is healthy.

Technical Aspects

- Dry Solids (78-87%)

- Acidity of 10 gm (40ml of N/50 NaoH )

- Sulphated Ash (0.50% Max)

- Starch Absent

- Colorless to slightly yellowish

- PH of 50% solution (4.5-5.5)

- Dextrose Equivalent (38-52%)

- S02 (400ppm max) for confectionery uses

- Clarity of 50% Solution (Clear)

Product Packaging

- 80-85 Brix 300 KG DRUM

- 70-75 Brix 280 KG DRUM

Uses & Benefits of Liquid Glucose

Crystallizing: Liquid glucose is used in almost every type of confection, particularly hard candies, ice –creams, jams & jellies

Flavor Enhancer: Liquid glucose performs to bring out the delicate flavor in candies.

Texture Enhancers: Liquid glucose provides a smooth body and smooth texture to ice creams and other frozen desserts.

Stabilizer: Liquid glucose acts as a stabilizer and improves the shelf life of the product.

Adjuncts: Adjuncts are used to supplement malted barley in brewing and liquid glucose has a number of advantages as an adjunct, as it is completely soluble and economical, easy to handle and adaptable. Liquid glucose is ideal for high gravity brewing techniques which increases the overall brew house efficiency and yield.